What we do

There are no geographical borders when it comes to the dream of complete waterproofing.

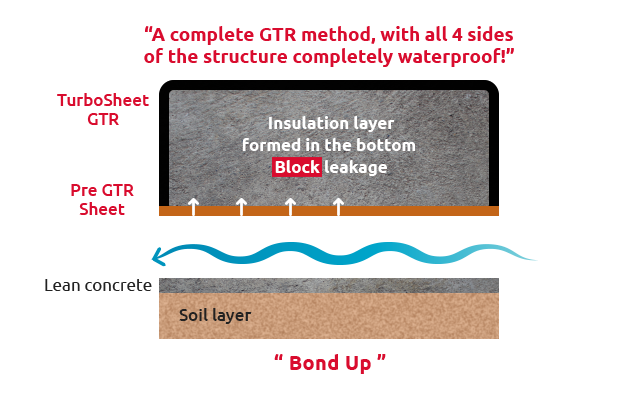

Pre-GTR Bond Up Membrane Sheet

Pre-GTR Bond Up Membrane Sheet

Eco-friendly Inorganic Bond Up Membrane Sheet (New Technology No. 740)

Size 1M *10M

THK 3.0

“Pre-applied membrane sheet with fresh concrete substrate with eco-friendly inorganic modified polymer that match performance standards mentioned in “Framework Act on Low Carbon, Green Growth.”

Keeps a strong bond with the reinforced concrete slab when poured after waterproofing layer is formed

Strong adhesion to concrete regardless of weather conditions (UV exposure, humidity, and temperature changes) after waterproofing layer is formed

Strong adhesion against concrete even when exposed to water after waterproofing layer is formed

No solvents or primer required, thereby ensuring safety of workers working in a closed environment

Shorten construction time and decrease in cost from easy application

Type / Purpose and Features

- Architecture : Structures including rooftops, underground parking, etc.

- Civil engineering : Underground structures including railways, power plants, sewage treatments, utility tunnels, and underground roads

- Size 1M *10M

- THK 3.0

Product Characteristics

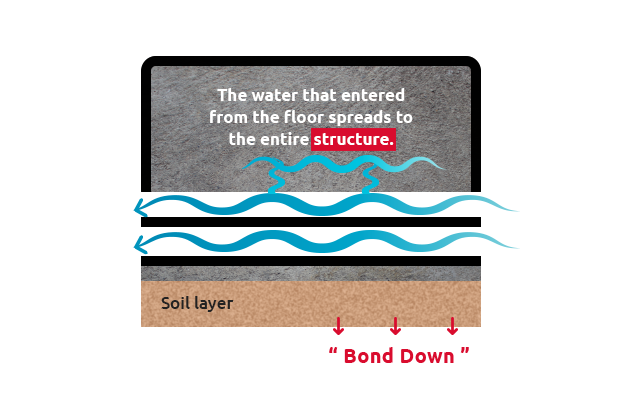

Uniqueness of bond-up

An inorganic material with similar thermal expansion and breathability to concrete, which allows for a stable application to concrete poured on the floor on site

-> Prevents any expansion in leakages and boosts watertightness, durability and waterproofing stability from damages in waterproof layer

Normal 3-side Waterproof System

Everything is done using the GTR waterproofing method

| Test Category | Unit | Quality Standard | Test Method | |

|---|---|---|---|---|

| Tensile strength | N/㎟ | ≥1.0 | KS F 4919 | |

| Internal cracking | - | No small cracks | ||

| Tensile strength | N/A | N/mm | ≥5.0 | KS F 4917 |

| Elongation | % | ≥15 | ||

| Tearing performance | N | ≥20 | ||

| Adhesion Performance | N/mm | Tensile strength ≥5.0 ≥70% to the butterfly direction |

||