C-rPET

Low-Temperature Methanolysis Depolymerization Technology Capable of Complete Chemical Decomposition

Re-New C-rPET Depolymerization Technology (Methanolysis technology

at room temperature and atmospheric pressure)

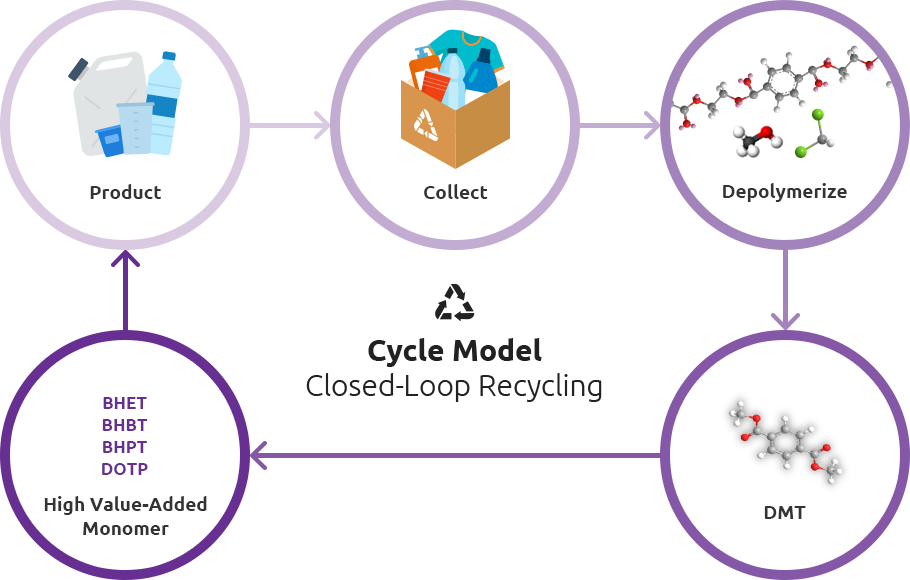

Renew System's C2C (Cradle-to-Cradle) approach, moving one step further to change the destiny of waste plastics

- Background of the Depolymerization Technology Development

- As global interest in the environmental problems and solutions such Circular Economy and Carbon Neutrality increases, chemical recycling technology that allows the repeated reuse of resources without waste in the entire process of production, consumption, and recycling has attracted great attention.

Several new chemical technologies are emerging. However, the commercially well-proven technologies are not available mainly due to the technical and economical barriers.

- Current State of Waste Plastic Recycling Technology

- Currently, in the recycling industry, open-loop recycling is mainly used to recover heat by pyrolysis of waste PET, or to produce low-cost and low-grade materials via mechanical recycling.Most technologies of industrial applications are limited to either mechanical recycling or thermal recycling, which are not sustainable.

Mechanical recycling is the most widely used method because of its simplicity. In this method, post-consumer plastics are physically reprocessed through sorting, crushing, and washing while maintaining the chemical structure of existing plastics.

However, mechanical recycling deteriorates quality of recycled plastics and limits the number of their recycle times.

- Chemical Recycling Technology of the Future

- For this reason, 'chemical recycling', which reproduces plastics that have the same quality as original one and can be recycled through a closed-loop approach with infinite repetition, is considered as an attractive alternative.

Conventional chemical recycling technology is slow and far from commercialized as the nature of process requires a lot of energy to remove pollutant, with its low profitability. Furthermore, it has a high risk of explosion due to the harsh reaction conditions under high temperatures and high pressure.

- Renew System's C-rPET Depolymerization Technology

- Renew System's chemical depolymerization technology is a low-temperature methanolysis that can completely decompose waste PET bottles or waste polyester fibers, which are commonly encountered in daily life, consuming a small amount of energy at room temperature.

This technology is capable of producing high value-added monomer, dimethyl terephthalate (DMT), with a high yield and high purity, by applying a low-cost catalyst with high reactivity at room temperature and introducing a process technology capable of controlling side reactions.

In addition, Renew System has developed a platform technology that can produce various high value-added renewable monomers at low temperatures below 100℃ by using the resulting DMT as a reaction intermediate. This multi-purpose eco-friendly material manufacturing method can flexibly respond to changes in the price of recycled materials or market demand, with operation characteristics that can manufacture a variety of products in the same process with minimal process variable control and change of input raw materials.

- Renew System's Efforts to Achieve a Plastic Circular Economy and a New Challenge to Create a Clean Environment

- In addition, Renew System has developed various technologies–low temperature glycolysis, room temperature alkaline decomposition, pre- and post-treatment technologies for organic and inorganic impurities– that can recycle colored and low-quality PET or waste polyester fibersto domestically and internationally commercialize the chemical recycling technologies of waste PET .

Renew System's technology is significant in that it can contribute to alleviating the waste plastic crisis, which is emerging not only in Korea but also around the world, and that it can obtain raw materials for petrochemicals from waste resources to replace them, which were entirely dependent on imports. - (We welcome all inquiries - crpet@re-new.co.kr)

Renew System's Chemical Depolymerization Technology

- Developed low-temperature methanolysis technology that can completely decompose waste PET at room temperature with minimal energy consumption

- Developed the technology to produce dimethyl terephthalate (DMT), a high value-added monomer, with a high yield and high purity

- Developed a platform technology capable of producing various high value-added regenerative monomers at low temperatures below 100℃ using the manufactured DMT as an intermediate compound.

- Developed various technologies that can recycle colored and low-quality PET or waste polyester fibers (e.g., low-temperature glycolysis, room-temperature alkali decomposition, pre- and post-treatment technologies for organic and inorganic impurities)

Low-Temperature Catalytic Methanolysis

(In this technology, methanol serves as a solvent and reactant to decompose PET)

Excellent depolymerization performance, a stable and economical process, and high product quality

- STEP1

- Pretreatment Process(Controlling impurities and improving the yield)

- STEP2

- Low-Temperature Methanolysis(Temperature ≤ 60℃, reaction time: 2h)

- STEP3

- Separation and Purification(Solvent recovery, intermediate product purification)

- STEP4

- Blood Changer(DMT2X technology)

Characteristics of Renew System's Depolymerization Technology

- Complete decomposition of PET at room temperature

- Low-cost catalytic methanolysis

- Improved production yield through the reaction mechanism control

- High purity, high value-added monomer production

- Low energy

Low carbon emission

Eco-friendly technology